Summary:Copper shunts are devices used in electrical meter applications to provide a low-resistance path for...

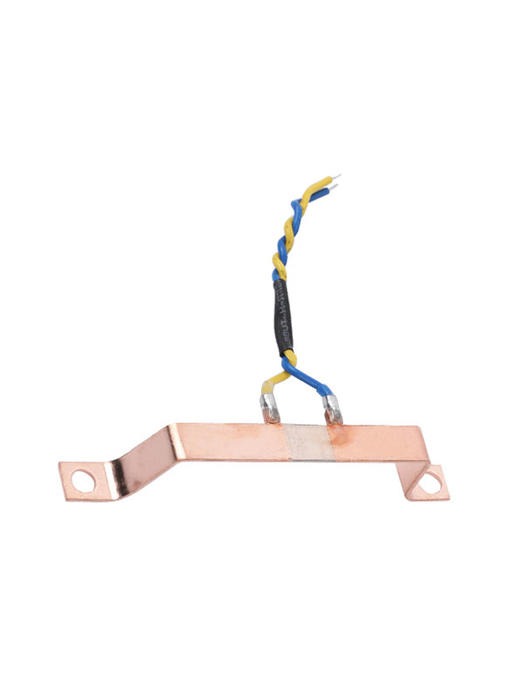

Copper shunts are devices used in electrical meter applications to provide a low-resistance path for the flow of electrical current. They are typically used in energy meters, such as kilowatt-hour meters, to measure the flow of electrical energy from a power source to a load.

Copper shunts are made from high-conductivity copper and are designed to have a low resistance, which helps to minimize the impact of the shunt on the overall accuracy of the meter. They are typically designed to handle high current levels and are typically specified by the maximum current and voltage they can handle.

Copper shunts are often used in conjunction with other meter components, such as current transformers or voltage transformers, to measure the electrical parameters of a circuit. They are also commonly used in conjunction with microcontrollers or other meter electronics to perform additional functions, such as data logging or communication with a remote monitoring system.

When choosing a copper shunt, it is important to consider factors such as the maximum current and voltage levels to be handled, the accuracy requirements of the meter, and any environmental or regulatory requirements.

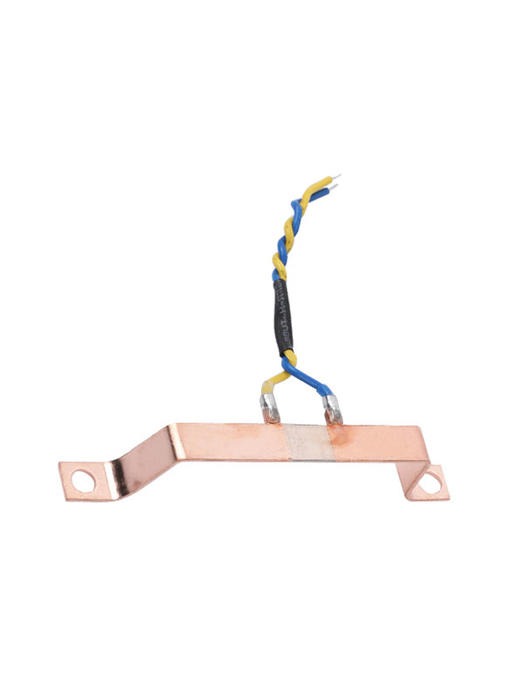

An electron beam welding shunt is a device that is used to measure the current flowing through an electron beam welding system. It is typically used in conjunction with an electron beam welding power supply, which is a device that generates the high-energy electron beam that is used to weld metal components.

An electron beam welding shunt is connected in parallel with the welding circuit, and it is designed to allow a portion of the current to flow through it while the rest of the current flows through the circuit. The shunt measures the current flowing through it and sends this information to a meter or other monitoring device, which uses it to calculate the total current flowing through the circuit.