Summary:The physical construction of a transformer is crucial to its proper operation. It must be made using...

The physical construction of a transformer is crucial to its proper operation. It must be made using laminated steel sheets that are separated by an air-gap. The laminations help to minimize the resistance of the magnetic core. Laminations also reduce the path of the eddy current. Besides, they ensure that both windings are wound in the same core.

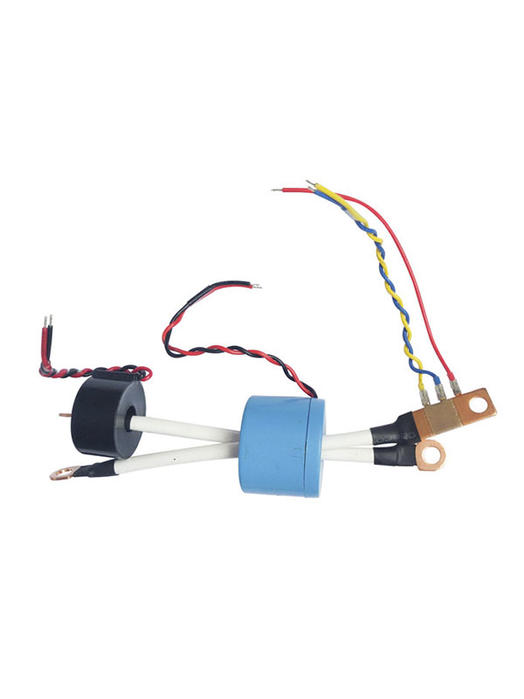

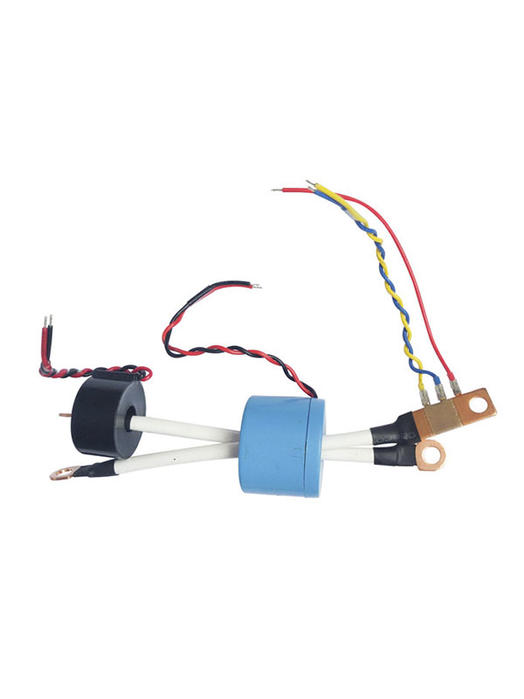

Insulating components of a transformer protect the core and windings and provide support to external accessories. These components are usually made of fabricated rolled steel plates and equipped with inbuilt cooling tubes and lifting hooks. Some transformers also employ aluminum sheets to reduce their weight. Terminals and bushings are other important components. They connect supply and load cables and are connected to the windings conductor.

The basic

components of a transformer are the core, primary windings, and secondary windings. They also include the protection relay and the insulating material. Other important components of a transformer include the conservator, the oil tank, the explosion vent, and the tap changer. Each of these parts plays a key role in the overall operation of the transformer.

The primary and secondary windings of a transformer are made of copper. They are insulated and have two different magnetic circuits. The main limb is the core, while the side limbs carry half of the flow. The middle limb is generally two times as large as the outer limbs. The windings travel around the inside of the middle arm and the main ring to eliminate leakages.

1: Working environment temperature: -30 ° C~55 ° C

2: Working environment humidity: relative: 10%~90%: Absolute: <29g/m

3 without condensation 3: Storage ambient temperature: -40 ° C ~70 ° C

4: Working altitude: 0-4000 meters, rated power below 2000 meters, above 2000 meters, for every 100 meters rise, derating 1%